Continuous Process Control AUPRO

The AUPRO series was developed to create experiences that enable the development of continuous process control skills by applying a variety of control methods in practice.

Skills and competencies

- Configuring and using sensors and instruments for analog variables (level, flow, temperature, and pressure)

- Controlling flow through electric and pneumatic valves

- Controlling flow through inverters and pumps

- Implementing and tuning P, PI, and PID control loops

- Implementing and tuning level, flow, temperature, and pressure control loops

Main Differences

Main Benefits

Technological

highlights

The sensors and instruments used are industrial, allowing students to become familiar with and learn how to use equipment they will encounter in the field.

Controlling inverters through networks and using PLCs that support the MQTT protocol allows for the implementation of Industrial IoT practices and connectivity with cloud systems.

Siemens is one of the most well-known and widely used brands globally, offering a development platform for all its Automation solutions, the TIA Portal.

Altus is a Brazilian automation company with a presence in important markets such as oil and sanitation.

The included supervisory licenses allow for the exploration of SCADA system development, typically created for monitoring control systems.

Through the simulator (digital twin), it is possible to practice control and tuning of control loops. The simulator can be controlled by both physical and simulated PLCs or even through MATLAB or LabVIEW. Additionally, the simulator can display only the devices relevant to each control loop, facilitating process understanding and P&ID comprehension.

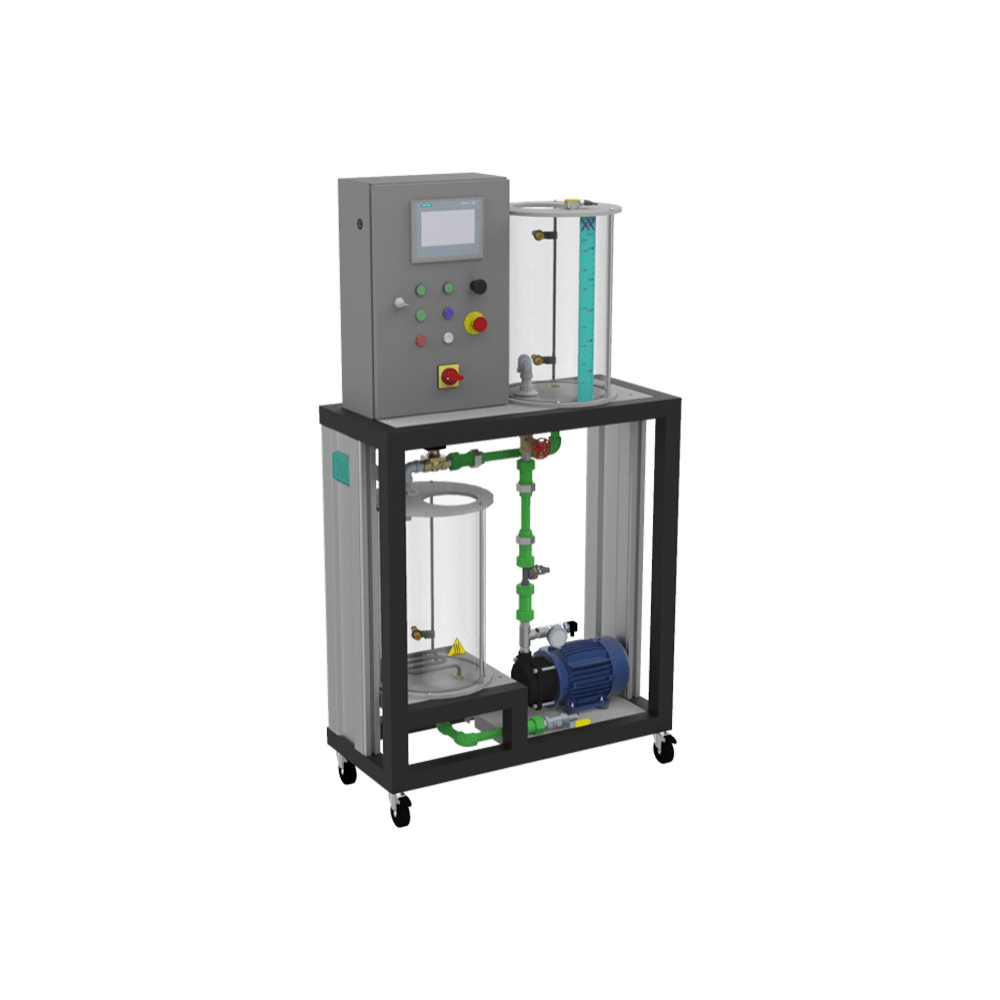

NVPT control plant (Level, flow, pressure and temperature

With this plant, it is possible to carry out continuous process control practices involving variables such as level, flow, temperature, and pressure. With integrated PLC and HMI and simple sensors, it is the ideal solution for those who want to focus on the study of control technologies such as PID and others.

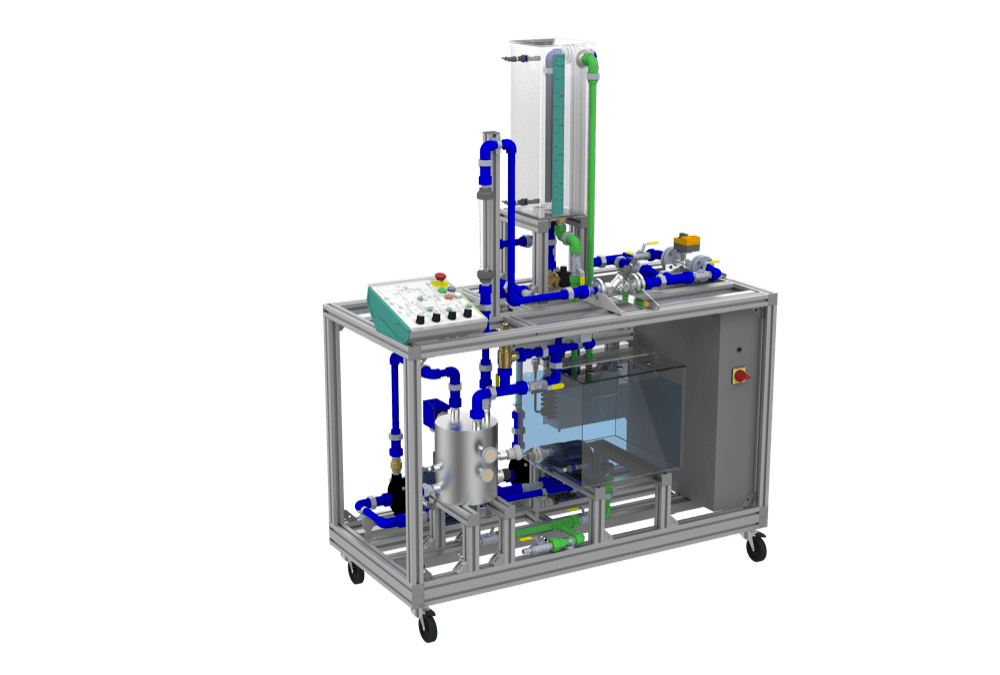

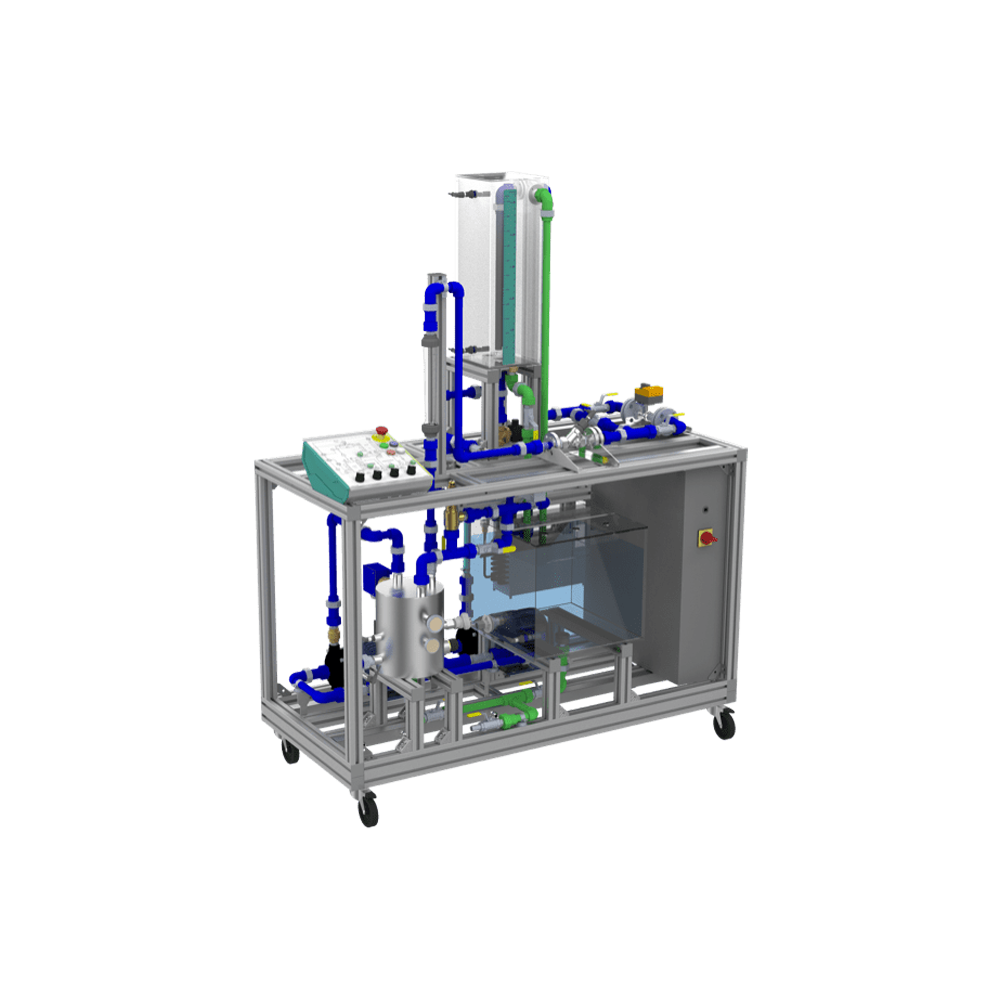

Instrumentation and process control plant

This instrumentation plant has a more comprehensive process than AUPRO2000. In addition, market instruments are used to measure the variables, making it more suitable for courses with an emphasis on instrumentation and control, aimed at the continuous process industry.

FILL FORM AND RECEIVE OUR CATALOG IN YOUR EMAIL

Courseware

The teaching kits are accompanied by rich teaching material with a practical focus, which provides practical proposals aimed at developing skills and competencies.

The Student Guide is offered, with proposals for practical activities, the Educator’s Guide, with answers to activities and teaching guidance on the products, and video tutorials to assist in using the tools when using the kit.