Control and Supervision AUSUP

This series provides essential kits for any automation laboratory, allowing the study of automated control systems through PLCs (Programmable Logic Controllers) and the technologies used to supervise these systems using HMIs (Human-Machine Interface) and SCADA (Supervisory Control and Data Acquisition) software.

Skills and competencies

- Understanding the internal structure of a PLC

- Programming in different programming languages

- Establishing communication between HMI and PLC

- Understanding the industrial networks used in PLCs

Main Differences

Main Benefits

Technological

highlights

The PLC (Programmable Logic Controller) is the main component of an automation system. Learning how to program this device is essential for training in the fields of control and automation, mechatronics, electronics, and related areas. Local supervision of machines or processes also requires mastery of HMI (Human-Machine Interface) programming and SCADA (Supervisory Control and Data Acquisition) software.

PLCs are increasingly equipped with connectivity features for industrial networks and the Internet of Things (IoT). The PLCs chosen for this family are rich in both industrial protocols and IoT protocols. In this series, we use PLCs from manufacturers with a significant presence in the market: Siemens and Altus.

Siemens is one of the most well-known and widely used brands globally, offering a development platform for all its Automation solutions, the TIA Portal.

Altus is a Brazilian automation company with a presence in important markets such as oil and sanitation.

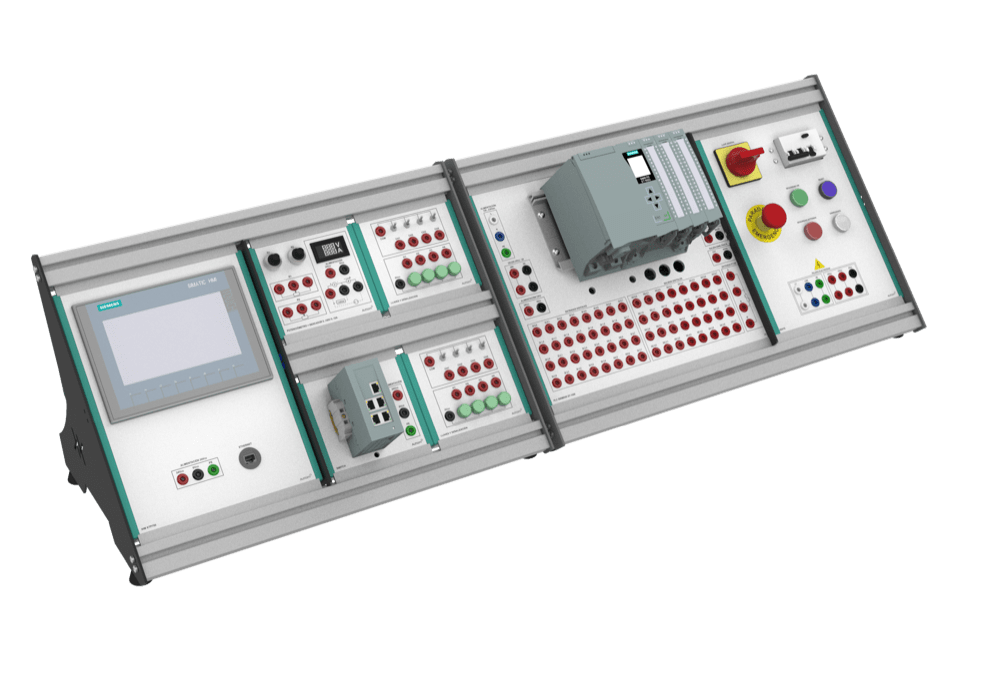

The PLCs that come with the Dock Station kits are called compact PLCs and are typically used in machines and small processes. They have integrated inputs and outputs with the CPU.

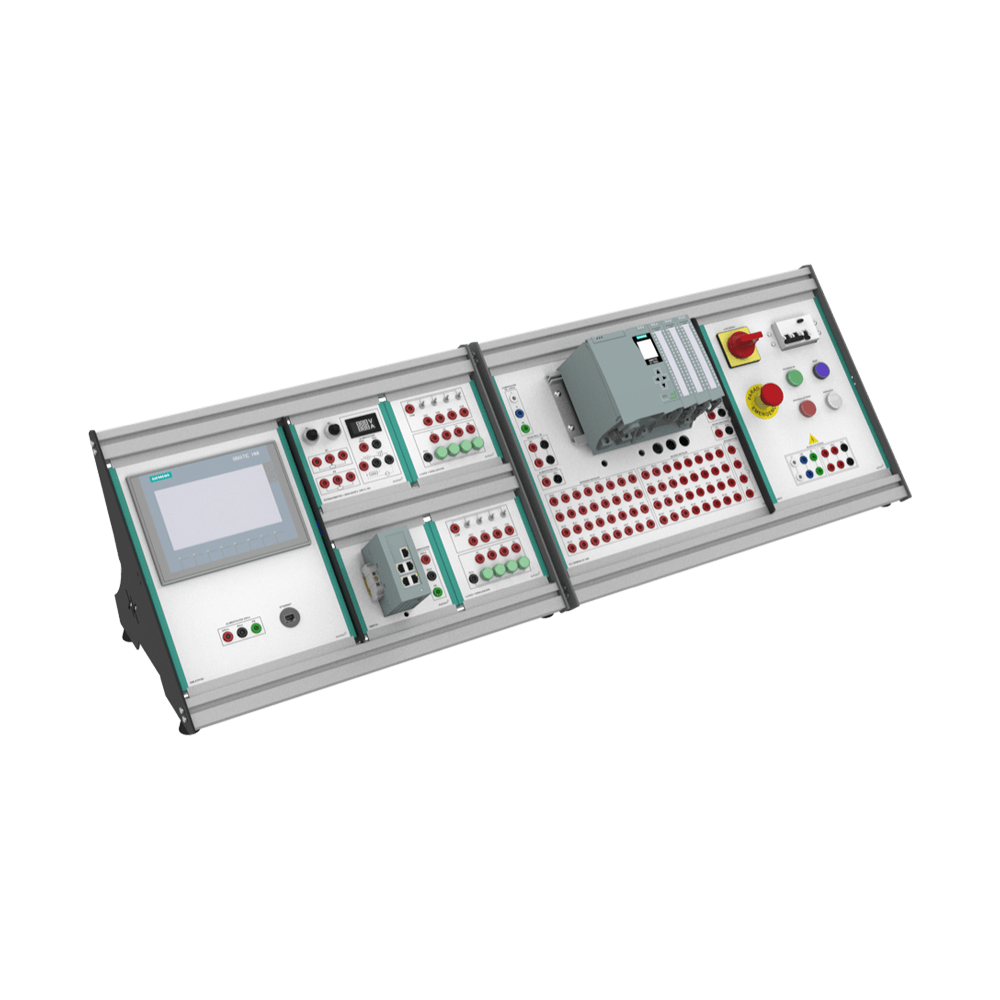

The PLCs that come with the Rack construction kits are modular PLCs, typically used in more complex processes that require more processing power. They have expandable input and output cards according to the application’s needs. They offer higher processing speed, more computational resources, and advanced functions.

Through the Sismaq Simulator, you can expand the kit’s usage by controlling digital twins of 5 industrial machines using the physical PLC.

Dock Station

Estes kits são focados no estudo das tecnologias da camada 2 da ISA-95, ou seja, sistema de controle e supervisão. Em configuração compacta, no formato dock station, estes kits trazem CLPs e IHMs dos principais fabricantes, e recursos que permitem explorar suas entradas e saída analógica e digitais.

Rack Station

Estes kits são focados no estudo das tecnologias da camada 2 da ISA-95, ou seja, sistema de controle e supervisão. De configuração modular em rack , estes kits trazem além de CLPs e IHMs dos principais fabricantes, recursos que permitem explorar suas entradas e saída analógica e digitais e módulos adicionais como inversores e etc.

FILL FORM AND RECEIVE OUR CATALOG IN YOUR EMAIL

Courseware

The teaching kits are accompanied by rich teaching material with a practical focus, which provides practical proposals aimed at developing skills and competencies.

The Student Guide is offered, with proposals for practical activities, the Educator’s Guide, with answers to activities and teaching guidance on the products, and video tutorials to assist in using the tools when using the kit.