Electrical Maintenance ETMAN

The kits in this series allow you to work on diagnosing faults in electrical systems, such as electrical control panels, speed control using frequency inverters, direct starting, star-delta starting, and compensating starters for three-phase induction motors, starting three-phase induction motors using a static starter (soft starter), automatic power factor correction, and control of level and temperature.

Skills and competencies

- Performing measurements and diagnostics in electrical systems

- Diagnosing and repairing various types of electrical circuits

- Configuring frequency inverters

- Configuring static starters (soft starters)

- Configuring power factor controllers

Main Differences

Main Benefits

Technological

highlights

Frequency inverters are an increasingly used technology for motor drives and industrial automation.

The use of soft starters (static starter) with controlled motor starting methods brings several efficiency and protection benefits.

Automatic power factor correction systems use specialized controllers to dynamically control the power factor of an installation by adding and removing capacitor banks based on the measured and configured values.

Process control systems use PID loops for level and temperature control.

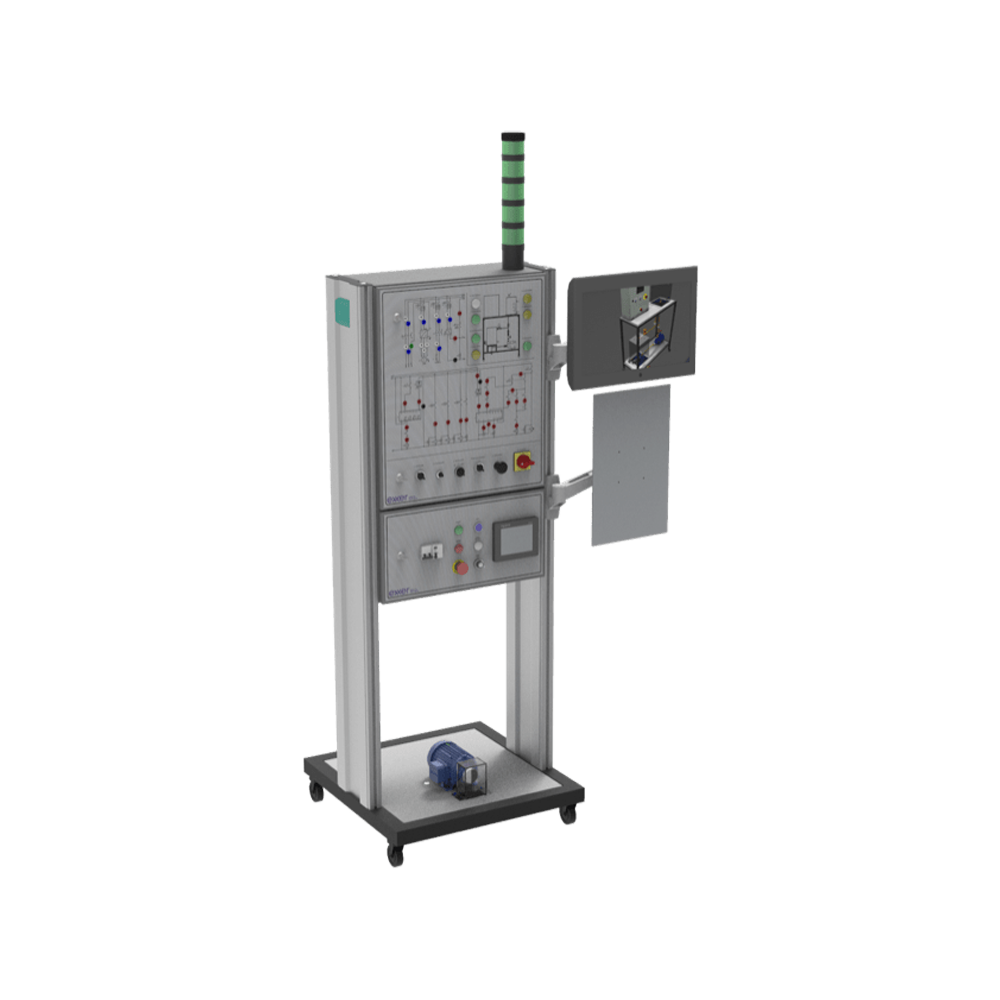

Control and speed maintenance workbench

Os kits da série ETMAN são voltados para práticas de análise de circuitos, detecção e correção de erros, incluindo simulação de defeitos. A bancada de manutenção de controle de velocidade explora estas práticas aplicadas aos sistemas de motores controlados por inversores de frequência.

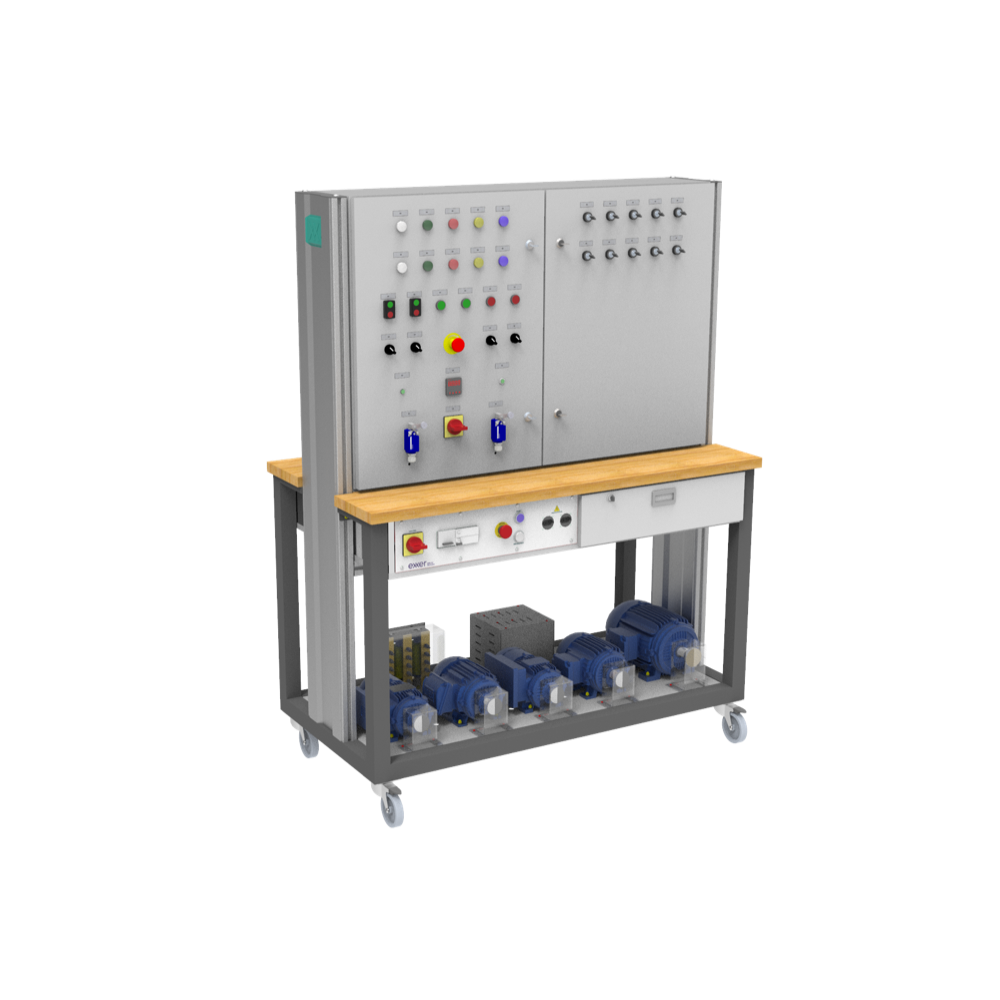

Engine starting maintenance workbench

Os kits da série ETMAN são voltados para práticas de análise de circuitos, detecção e correção de erros, incluindo simulação de defeitos. A bancada de manutenção de partida de motores explora estas práticas aplicadas aos circuitos de partida de motores trifásicos.

Static starter maintenance workbench

The ETMAN series kits are focused on circuit analysis practices, error detection and correction, including fault simulation. The static start maintenance bench explores these practices applied to three-phase motor starting using static starters (soft-starters).

Maintenance workbench for power factor correction

Os kits da série ETMAN são voltados para práticas de análise de circuitos, detecção e correção de erros, incluindo simulação de defeitos. A bancada de manutenção de fator de potência explora estas práticas aplicadas aos sistemas de controle automático de fator de potência.

Level / temperature control maintenance workbench

Os kits da série ETMAN são voltados para práticas de análise de circuitos, detecção e correção de erros, incluindo simulação de defeitos. A bancada de manutenção de controle de nível e temperatura explora estas práticas aplicadas aos sistemas de controle de processos contínuos de nível e temperatura.

Command panel maintenance workbench

Os kits da série ETMAN são voltados para práticas de análise de circuitos, detecção e correção de erros, incluindo simulação de defeitos. A bancada de manutenção de quadro de comandos explora estas práticas aplicadas aos problemas mais comumente encontrados em quadros de comandos elétricos.

FILL FORM AND RECEIVE OUR CATALOG IN YOUR EMAIL

Courseware

The teaching kits are accompanied by rich teaching material with a practical focus, which provides practical proposals aimed at developing skills and competencies.

The Student Guide is offered, with proposals for practical activities, the Educator’s Guide, with answers to activities and teaching guidance on the products, and video tutorials to assist in using the tools when using the kit.