SMART 4.0 SMART

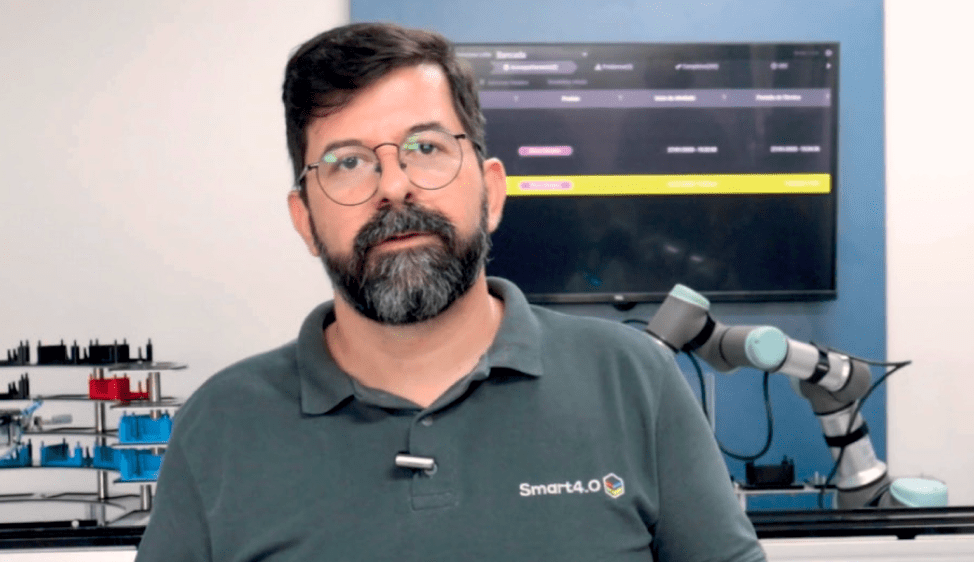

The SMART 4.0 series was developed with the aim of facilitating the teaching process of Industry 4.0 enabling technologies.

Main Differences

Main Benefits

Technological

highlights

Collaborative robotics and computer vision: A collaborative robot is an industrial robot designed to interact safely with humans. Associated with computer vision systems that use artificial intelligence, we achieve safe, autonomous, and flexible robotic systems. In the SMART series, these resources are available for learning manipulation, assembly, and quality control processes.

Industrial IoT: IoT (Internet of Things) is one of the most important technologies in the fourth industrial revolution. In this context, it is referred to as Industrial IoT, distinguishing it from other usage scenarios. In the SMART 4.0 series, this technology is applied to both sensor device communication and PLC communication using the MQTT protocol. In both cases, data is sent to cloud platforms where dashboards can be created to present it.

Cybersecurity and virtualization: IT technologies are increasingly present in industry, including cybersecurity, corporate networks, edge computing, and virtualization. All of these topics are present and can be practically explored on the SMART 4.0 platform.

Manufacturing Execution System (MES): In Industry 4.0, not only the production process is automated, but also production management. This is done through software called MES (Manufacturing Execution System). This technology integrates orders from online sales systems with automated production processes, managing and sequencing these orders and inventories. In the SMART 4.0 series, this technology is also present and available for study and practical application.

Systems integration: One of the main challenges of Industry 4.0 is the integration of all systems and protocols present in the industry. The skills to tackle this challenge are developed in the SMART 4.0 series through connectivity technologies and databases.

Digital twin: The use of a digital twin is an important factor for increasing productivityand optimizing manufacturing processes. This simulation technology is also present in SMART 4.0, with the additional benefit of being usable for student practices, even in their homes, enabling online or blended courses.

SMART 4.0 modular

The Smart 4.0 is a complete laboratory that integrates Industry 4.0 technologies into an automated and digitized factory. Composed of various stations, it constitutes a flexible manufacturing system with multiple layers of software that make it the ideal solution for studying modern manufacturing systems of Industry 4.0.

SMART 4.0 Concept

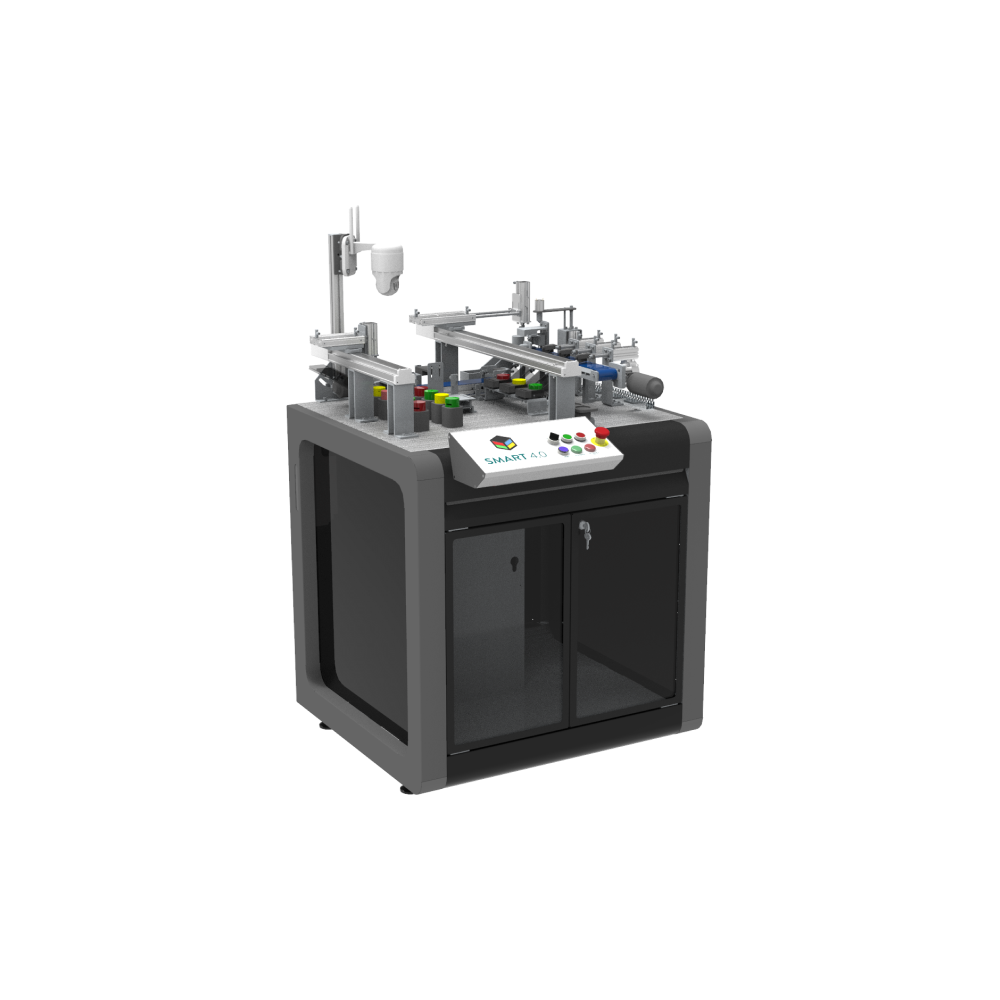

The Smart 4.0 Concept is a compact version of the teaching platform for Industry 4.0. It brings together various Industry 4.0 technologies in a single station and enables a complete manufacturing process. Sharing various technologies with the modular version, it is an introductory solution for the competencies of the fourth industrial revolution.

MoMa Station (Mobile Manipulator)

Mobile station composed of a mobile robot (AMR) and a collaborative arm, which integrates with the production processes and management software of SMART 4.0, enabling the transport of materials to the plant.

TI/TA Station

With modular configuration, safety with NR-12, included development software, protection of main components, and included didactic material.

FILL FORM AND RECEIVE OUR CATALOG IN YOUR EMAIL

Courseware

The teaching kits are accompanied by rich teaching material with a practical focus, which provides practical proposals aimed at developing skills and competencies.

The Student Guide is offered, with proposals for practical activities, the Educator’s Guide, with answers to activities and teaching guidance on the products, and video tutorials to assist in using the tools when using the kit.